In recent decades, environmental problems have become the focus of human attention. The disposal of plastic waste has always been a problem. It takes hundreds of years to decompose, which puts a great burden on the earth. So the plastic packaging industry has been working hard on alternatives. In recent years, recyclable packaging bag solutions have become more and more mature and can completely replace traditional packaging bags to meet the demand for packaging bags for various products, such as coffee, tea, underwear, etc.

I believe that many people still don’t know much about recyclable packaging bags, and have been hesitating whether now is a good time to replace their existing packaging with recyclable ones. Therefore, we intend to use this article to let you know as much as possible about recyclable packaging bags.

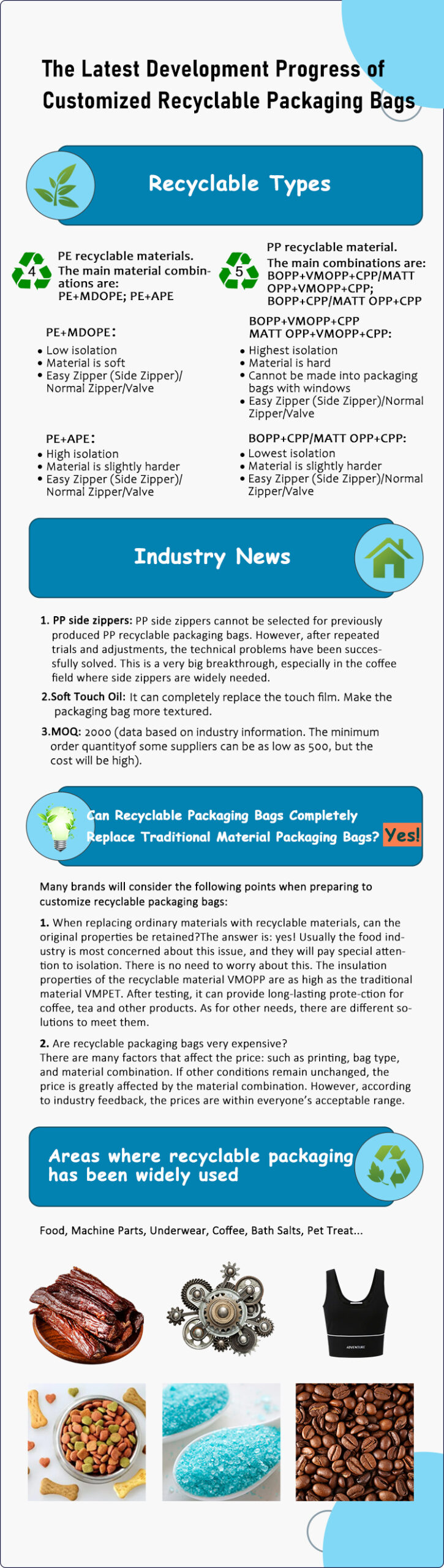

1. Classification of recyclable materials

We now classify recyclable materials according to basic material types. This is a classification standard proposed by the United States and is also used internationally. There are two major categories in total: PE recyclable materials and PP recyclable materials.

1.1. PE recyclable materials

PE is a thermoplastic resin material with good low temperature resistance, resistance to most acid and alkali corrosion and good chemical stability. The two main popular PE recyclable packaging bags are: PE+MDOPE; PE+APE.

PE+MDOPE: Cheap in price, worse insulating properties than APE, and the unprinted state is a transparent bag. Can be made into window packaging bags. The material itself is bright. If you want to achieve a matte effect, you need to apply matte oil.

PE+APE: The price is slightly more expensive than MDOPE, the insulation is better, and it is slightly harder than MDOPE. Can be used as window packaging bags.

The material itself is bright. If you want to achieve a matte effect, you need to apply matte oil.

Brand owners can choose PE side zipper (easy zipper) / PE valve when choosing PE packaging bags.

1.2.PP recyclable materials

Polypropylene is a thermoplastic synthetic resin with excellent properties. It is colorless and translucent. It has chemical resistance, heat resistance, electrical insulation, high strength mechanical properties and good high wear resistance processing properties. It is widely used in food and medicine. Package. The main PP recyclable packaging combinations on the market are: BOPP+VMOPP+CPP/MATT OPP+VMOPP+CPP; BOPP+CPP/MATT OPP+CPP

VMOPP: This is the most insulating recyclable material, equivalent to traditional VMPET. Foods that require high insulation usually choose VMOPP, but this material cannot be made into packaging bags with window.

CPP: Transparent, non-isolating, cheap, suitable for clothes and other products that do not require isolation.

2. The latest trends in the industry

I have just given you a introduction to the two major categories of recyclable materials. I believe you already have a preliminary and systematic understanding of recyclable packaging. Then I will share with you the latest trends in the industry to help you understand the field of recyclable packaging bags. degree of development.

2.1.PP side zipper

For a long time, due to technical problems, PP packaging bags could not be equipped with PP side zippers. This has influenced many brands to choose customized PP recyclables, especially in the coffee industry where side zippers are widely used. But recently, through trial and error, we have solved the technical problem and PP side zippers can also be installed.

2.2.Soft Touch Oil

One of the materials in traditional packaging bags is tactile film, which will increase the texture of the packaging bag and make your packaging bag more advanced than other brands. In order to achieve this function, we can spray a layer of soft touch oil during production, and the actual touch will be the same.

2.3.MOQ 2000

With the continuous development of recyclable materials, the program continues to improve, and the minimum order quantity for each customized bag is as low as 2,000. If you choose digital printing, the minimum order quantity for each style is 500.

We will continue to update you with the latest news in the field of recyclable packaging bags.

3. Industry prospects

At present, the solutions for recyclable packaging bags and compostable packaging bags are very comprehensive, and they can basically achieve a comprehensive replacement of traditional packaging bags. However, compostable packaging bags are not as popular as recyclable packaging bags due to their special properties (biodegradability). Especially in the food field, packaging bags need to provide longer-lasting and more efficient protection, and recyclable packaging bags will be better in this regard.

Of course, the specific choice of environmentally friendly packaging bags depends on your specific needs. If you are interested, please contact us: https://mylarbag.net/contact/. We can provide you with various samples for free.