In the last article, we introduced compostable materials for packaging bags: https://mylarbag.net/how-to-choose-the-right-environmentally-friendly-material-coffee-bag/

In the new article, we will introduce the most common coffee packaging bag materials. So far, compostable coffee packaging bags cannot completely replace traditional coffee packaging bags. Affected by shelf life and cost, coffee bags made of traditional materials still account for a large proportion.

PE

PE film is a simple polymer material with good weather resistance, light stability, thermal insulation and mechanical properties. It is widely used in actual life and production. Because PE film is corrosion-resistant, non-toxic, waterproof, and has high thermal shrinkage performance, it is often used as the inner layer of food packaging bags, that is, the heat-sealing layer. In addition, PE film can also be used as a printing layer in food packaging bags.

Traditional coffee packaging bags often use food-safe PE film as the inner material, which can provide ideal protection for coffee beans or coffee powder.

PET

Transparent PET material is very popular in the production of coffee packaging bags. PET has better performance than traditional BOPP film:

- Heat distortion temperature and long-term service temperature are the highest among thermoplastic general-purpose engineering plastics, and its mechanical properties are slightly affected by high and low temperatures.

- Low gas and water vapor permeability, excellent gas barrier, water, oil and odor performance, fully meet the coffee preservation requirements

- High transparency, can block ultraviolet rays, good gloss

- Non-toxic, tasteless, hygienic and safe, can be directly used in food packaging.

- It has good mechanical properties, the impact strength is 3~5 times that of other films, and it has good folding resistance.

So PET is often used as the outer layer of coffee packaging bags.

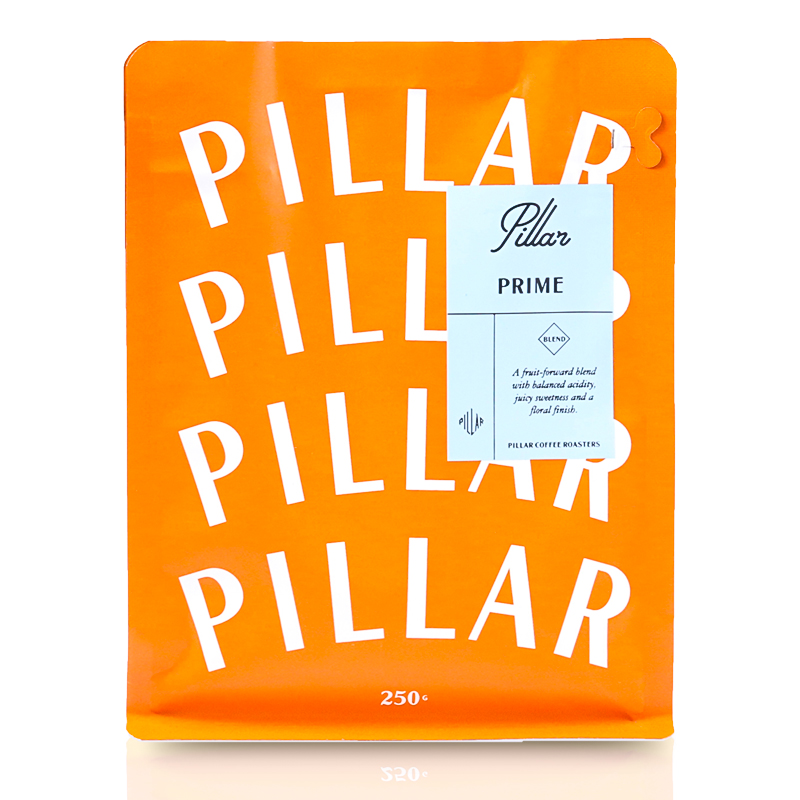

In addition, if you apply matte ink on the outside of the PET film, you can achieve a full or partial matte effect, that is, UV printing, which will make the product more design, as shown in the figure:

Matt OPP

Mattopp is a transparent matting film. It is often used as the outer packaging of coffee packaging bags. Superior stability, high temperature resistance, impact resistance.

- lLow gas permeability

- lFood safety grade

- lGood thermoplasticity

The picture is the rendering of the coffee bag made of Mattopp film:

Kraft Paper

Everyone knows kraft paper well, it is a very common material, and it is widely used in traditional coffee packaging bags and biodegradable coffee packaging bags.

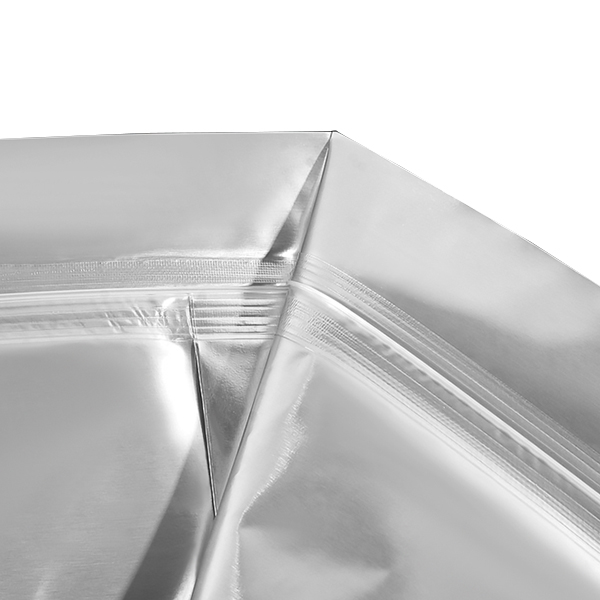

Aluminum Foil

Aluminum foil has the best barrier properties to moisture and oxygen among all materials, so it can provide the best protection for coffee beans or coffee grounds. Although the price of aluminum foil will be higher than other metal barrier materials, if you want coffee beans to be well protected, we recommend that you choose aluminum foil as an insulating layer to ensure the taste of coffee beans.

VMPET

The barrier properties of VMPET to moisture and oxygen are second only to aluminum foil. VMPET is an aluminized film, which combines aluminum powder with PET evenly. The cost will be lower than aluminum foil, and it can also provide long-term protection for coffee beans. Therefore, most merchants will choose VMPET as the insulation layer of coffee packaging bags.

We only list some of the best and most common traditional coffee bag materials in this article. If you are also interested in other materials not mentioned, please contact us: https://mylarbag.net/ contact/